S.N.C 300, S.N.C 300 and S.N.C 800 for PVD - DLC & CVD

S.N.C 300, S.N.C 300 and S.N.C 800 for PVD - DLC & CVD

SNC Filtered arc technology PVD (Physical Vapour Deposition) is used to synthesize extremely hard, dense and smooth coatings.

A wide variety of superhard coatings and nanocomposites can be synthesized, namely, TiN, TiAlN, CrN, AlN, AlCrTiN and ta-C (tetrahedral amorphous carbon).

A filtered arc technology is economically favourable process. Patented SNC Y-shape filter removes atom clusters from the beam before deposition, but keeping high deposition rate.

S.N.C MAG

S.N.C MAG

MAG – vacuum coating machine devoted to deposition of oxides filmes , namely of titanium, aluminum, zirconium, zinc on surfaces of complex shape and for antiviral and antibacterial coatings by plasma-deposited metal/metal oxides Ag , Cu , TiO2, TiOx + metal , with oxygen flow control by feedback of plasma emission spectroscopy.

S.N.C R2R

R2R – vacuum roll-to-roll machine with magnetron sputtering of ultrathin metal/metal oxide antiviral and antibacterial coatings on nonwoven with oxygen flow control by feedback of plasma emission spectroscopy.

Coating Thickness Measurement Device

Coating Thickness Measurement Device

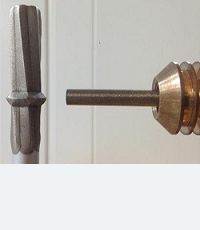

In this measuring technique, a spherical indentation is abraded in the coated substrate with a steel ball. The resulting indentation is measured and the results are used to calculate the coating thickness.

Supersonic Jet Cold Coating / 3D-Printing

Supersonic Jet Cold Coating / 3D-Printing

Gas dynamic cold powder spray + additive manufacturing

High adhesion(30-120 MPa)

Homogeneous structure of spraying

Low porosity (0.1-1%)

High electrical and thermal conductivity between the coating and the substrate

Any thickness(0.02 – 5 mm);

Smooth surface Rz = 20-40;

Possibility of any subsequent machining

S.N.C SuperJet Bonding Improver

S.N.C SuperJet Bonding Improver

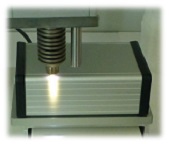

Atmospheric Pressure Plasma Device

Ideal Solution for In-Line Fine Surface Cleaning, Highest Activation and Coating

Copyright © 2013 NCI - Swissnanocoat SA 502161